In the few decades, with the developing and advancing drone tech, the uses and applications of drones have been evolving into a wide range. When drones first emerged on the market, they were strictly used for military purposes. Today, drones are used in many ways including delivery of small items, industrial site inspections, infrastructure monitoring, mapping, mining, crop monitoring, emergency response and security surveillance.

In the current times, the drone tech has acquired one of the biggest sector- the Mining Industry. The uses of drones in mining areas have eased the daily hustling of the workers. Aerial surveying has changed the overall face of mining operations and has revolutionised exploration. The application of aerial photogrammetry is a proven method of pit mapping and stockpile volume measurement, with a particular emphasis on 3D modelling and monitoring. The spatial data acquired in this way is used, for example, to create digital terrain models, orthorectified georeferenced imagery and topographic maps. This helps in mapping and deep mining.

Drones Acquiring the Mining Industry

In the current times, the drone tech has acquired one of the biggest sector- the Mining Industry. The uses of drones in mining areas have eased the daily hustling of the workers. Aerial surveying has changed the overall face of mining operations and has revolutionised exploration.

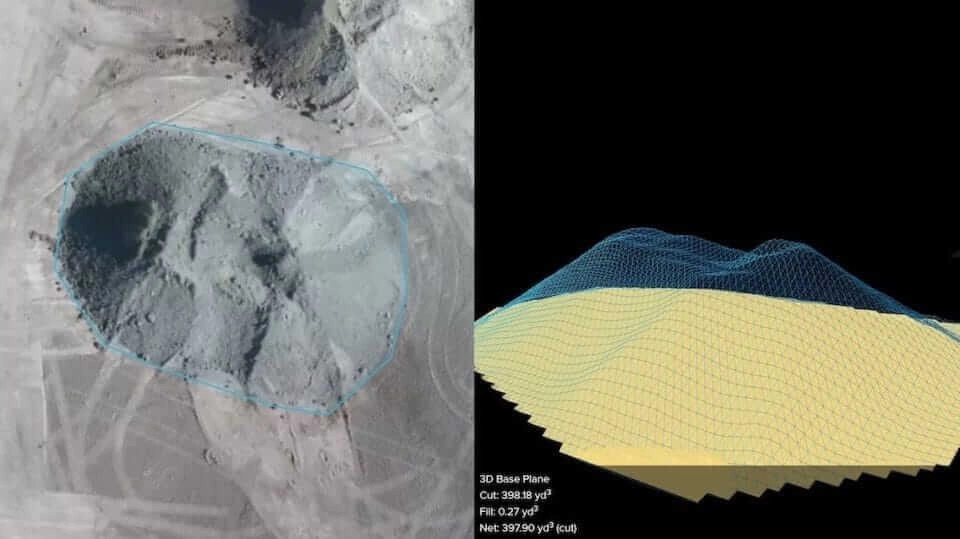

The application of aerial photogrammetry is a proven method of pit mapping and stockpile volume measurement, with a particular emphasis on 3D modelling and monitoring. The spatial data acquired in this way is used, for example, to create digital terrain models, orthorectified georeferenced imagery and topographic maps. This helps in mapping and deep mining.

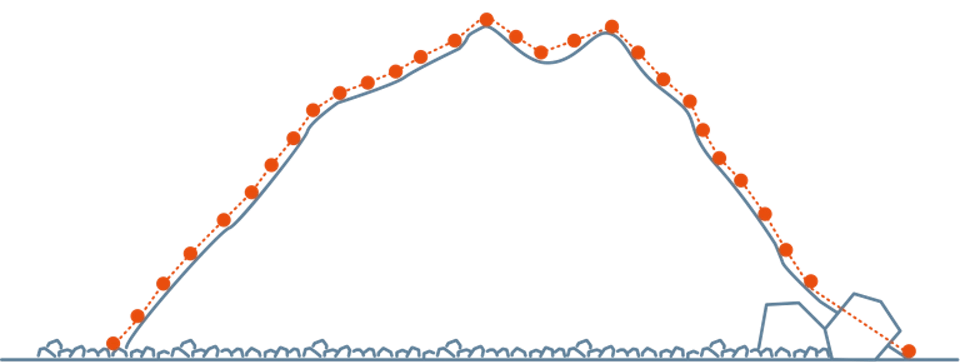

Display of slope, degrees and percentages from point to point.

Drone aerial images can be used to generate point clouds, digital surface models, digital terrain models and a 3D reconstruction of a mining site, including its stockpiles. As the point cloud contains several thousand data points, very accurate volume calculations can now be performed easily. With an accurate site model produced from drone aerial images, mine managers can efficiently design and manage site operations while collaborating across teams.

Aerial Survey Applications in Mining:

Site safety management-

Drones are being used for collecting visual data particularly of difficult and volatile areas such as deep and high terrains of a mine, highwalls, crests, and inside stopes. Further, aerial data capturing from blast sites, reduces the risk of exposure on the ground to such dangers.

Surveying and mapping-

Normally, surveying and mapping of mineral landscapes is a time-consuming process. By employing drones and a drone pilot instead of a piloted plane a mine can save around 90% of the cost per hour, and collect unlimited aerial data, including fine measurements by simultaneously capturing high end orthoimages.

Monitoring and inspection-

Mining is amongst the most unsafe industries for workers, especially those performing deep underground activities. Workers can be subjected to rock falls, extremely humid conditions, gas leaks, dust explosions or floods, amongst other hazards. Therefore, mining companies have used drones at underground mines to monitor and inspect deep underground shafts.

Drone data provides more precise volumetric measurements than traditional surveying methods, such as ground-based GNSS. This allows better valuation of stockpiles.

Mine Surveys Made Easy

Mining exploration can be easier with Aerial Surveys. Drone data can yield high-resolution orthophotos and DSM maps that support mining exploration projects in areas where it is difficult to navigate on foot. The use of drone’s costs only a fraction of the price of traditional manned aviation surveys. And compared to ground survey equipment, it would take a team of land surveyors’ weeks to collect the same amount of data that a drone can collect in a few hours.

Traditional GNSS Survey

Only a few data points can be collected, craters and steep slopes are often overlooked.

Aerial Survey

Hundreds of data points are collected, including steep slopes or craters sometimes invisible from the ground.

Outputs

Drone-generated data is a series of overlapping images containing geospatial information, which are stitched together through a process called photogrammetry. Each pixel of each image contains its own georeferenced location in space. The maps highlighted below are outputs that can be produced by all major photogrammetry software.

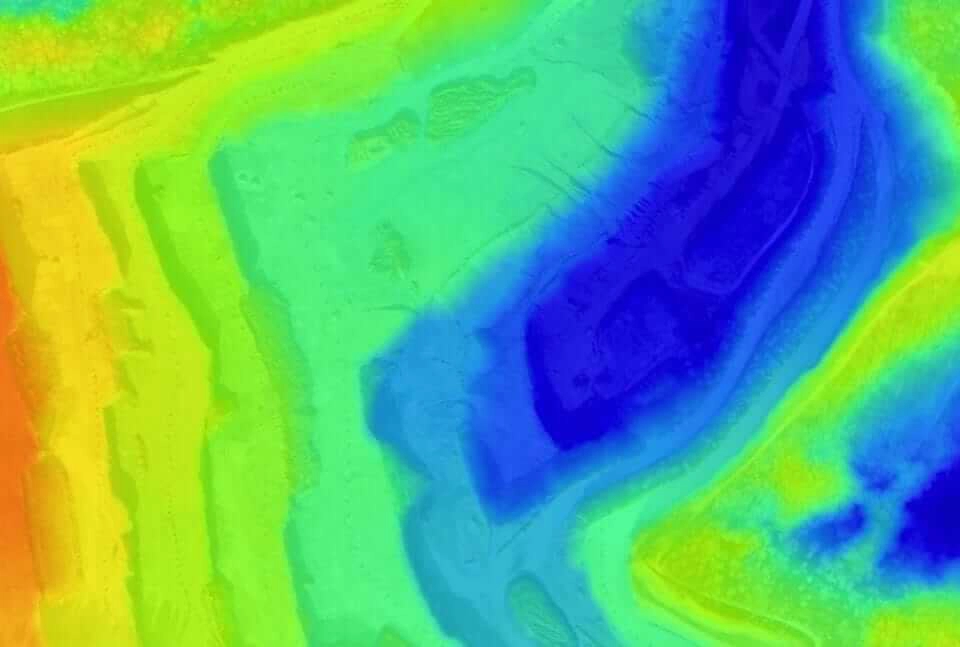

1. Digital terrain model (DTM)

After filtering objects such as buildings, machines and conveyor belts, drone images can be used to create digital terrain models, with each pixel containing 2.5D information (X, Y, and Z values of the highest altitude). These models allow you to identify stockpiles and pit changes, and to model water flows and wall collapses.

File formats: GeoTiff (.tif)

2. Orthomosaic Maps

Drone images are used to recreate highly-accurate orthomosaic maps of mining sites and quarries. Each pixel contains 2D geo-tagged information (X, Y) and can be used for distance and surface measurements.

File formats: geoTIFF (.tiff), .jpg, .png, Google tiles (.kml, .html)

3. 3D Point Cloud

A densified point cloud can be generated from drone images and data. Each point contains geospatial (X, Y, Z) and color information. It provides a very accurate model of a site for precise volume measurements and visual insights that enhance future planning.

File formats: .las, .laz, .ply, .xyz

Safer Mining Operation with Drone Tech

Now, Drones are widely used to decrease the risk of people getting harmed at mine sites. Geodesists, mineral surveyors and other specialist have no need to be physically present at survey sites, which can be dangerous. Staffs are no longer at risk, as nearly everything can be overseen by a drone and the information can be reported back to management, where they will be able to make further decisions without staff having to get involved and perform these tasks themselves.

Human workers are now being trained to operate drones from a safe location, rather than enter mines themselves to conduct resource estimates, which leads to survey operations becoming significantly safer with Aerial Surveys.